Coating for fluid film system – characterisation and benchmarking – Mr Peter Xia

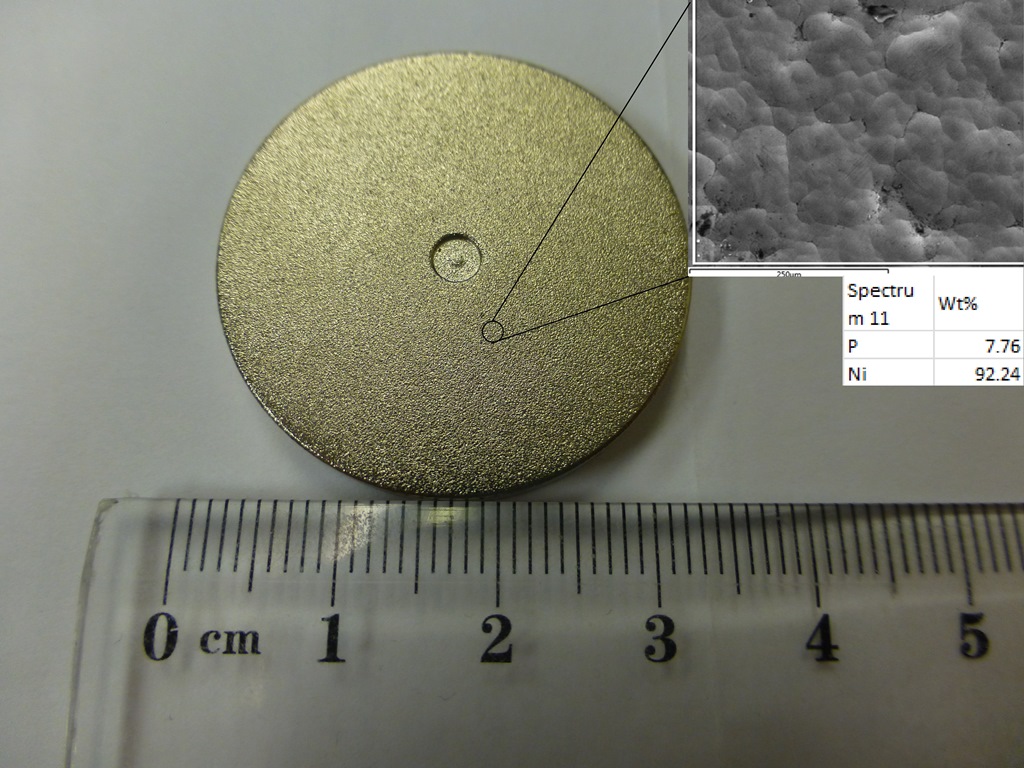

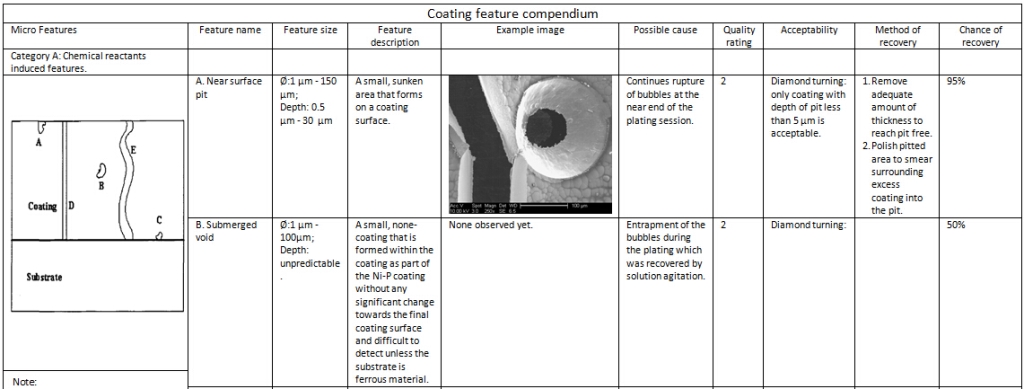

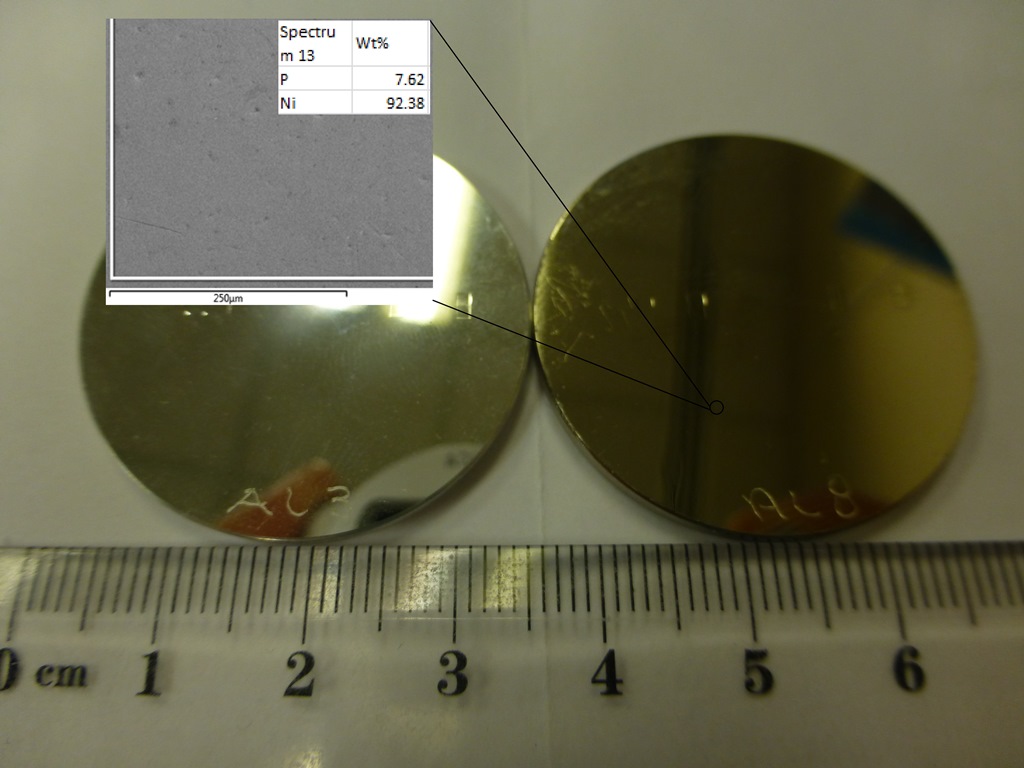

In an overarching project to reduce the number of defects found in electroless nickel phosphorus alloy (ENP) coatings on large diamond-turned components used in the next generation of reel-to-reel (R2R) printing stations, several commercial-graded ENP coatings have been tested for their ability to be diamond machined. This project focuses on the different processing stages of the ENP plating technique. It also focuses on the characterisation of unwanted features produced from immersion plating in response to such parameters as substrate material, substrate roughness and morphology, pre-plating treatment method, plating condition such as operating temperature, solution pH level as well as the effect that the requirement to achieve ‘thick’ coatings, in excess of 100 µm, has.

An inspection procedure for sampling each coating specimen was set up with the purpose of standardising an ENP coating route specifically for diamond turning applications. A coded grading system to quantify the quality of coating prior to further machining has been established. The main objective in doing so, is to create a “common-language” between plating facilities and ultra-precision manufacturers in need of a “good quality, optical finished, wear resistant” ENP coating.

The next stage is to test each coatings’ ability in diamond turning (with ranges of induced defect, various coating thickness and phosphorous content, as plated and heat-treated), and conclude the grading system with the quantified results in diamond machining ability. Together with the quality rating scheme, the grading system will be verified over a series of field test within the precision institute.

Peter Xia’s PhD research project is being undertaken at Cranfield University, supervised by Dr Sue Impey and Dr Heather Almond

Outputs

Conference Publications

Xia, P., Almond, H. and Impey, S. (2016). Investigation of pre and post plating surface roughness of electroless nickel phosphorus coated substrate for diamond turning application, Poster abstract, Proceedings of the 16th International Conference of the European Society for Precision Engineering and Nanotechnology, 30 May-3 June 2016, University of Nottingham, Nottingham, UK, 469-470.

Conference Presentations

Xia, P., Almond, H. and Impey, S. (2016). Investigation of pre and post plating surface of electroless nickel phosphorus (EN-P) coated substrate for diamond turning application, Poster presentation, 16th International Conference of the European Society for Precision Engineering and Nanotechnology, 30 May-3 June 2016, University of Nottingham, Nottingham, UK, P6.36.

Posters

Xia, P. (2016). Diamond machinable coating for large R2R rollers and hydrostatic bearings, Poster presentation to the EPSRC Centre for Innovative Manufacturing in Ultra Precision Steering Meeting Committee, 24 February 2016, Cranfield University, UK.

Xia, P. (2014). Optical quality wear resistant and diamond turnable coatings for aluminium rollers and hydrostatic bearings, Poster presentation, EPSRC Centre in Ultra Precision Mid-Term Review, 20 May 2014, Cranfield University, UK.

Digital Media

Xia, P. (2015). Coating for fluid film system – characterisation and benchmarking, PhD project video produced for an informal centre competition in 2015.