The Surface and Precision Centre has high level academic researchers and successful industrial experienced engineers who specialise in precision and ultra precision machine tool design and development, high performance and ultra precision machining, micro-engineering and metrology.

Established in 1968 as the Cranfield Unit for Precision Engineering (CUPE), the Precision Engineering Institute is internationally recognised as a centre of excellence in ultra precision machines and processes.

Today the Institute operates over 3000 square metres of thermally controlled precision, ultra precision, microengineering and surface structuring laboratories located at Cranfield and its Ultra Precision and Structured Surfaces (UPS2) laboratory at St Asaph, Wales. The laboratories house many unique ultra precision research facilities designed, manufactured and built by our own leading experts.

Having a strong emphasis on ‘practicing what it preaches’ the Precision Engineering Institute differentiates its activity by engagement in ‘large-scale’ science programmes where it acts as world-class engineering providers for complex machine systems and components. Such highly demanding projects provide a mechanism and stimulus for unique research, training and learning opportunities.

The Cranfield Precision Engineering Institute is a NASA approved supplier for space telescope mirrors including many of those being employed within the James Webb Space Telescope (the Hubble replacement). The Institute also fabricates systems and components for the UK’s National Physical Laboratory, the Rutherford Appleton Laboratory and the European Southern Observatory. Its industrial supported research includes significant contracts with aerospace, space, medical and optoelectronics orientated companies.

Core research themes include actuators and micro robotics; advanced metrology; diamond turning; dynamics and control; fluid film bearings; grinding; modal analysis; photochemical machining; plasma processing; precision machine design; reel to reel film handling and processing and surface structuring. The Institute operates laboratories with clear measurement traceability certification.

Research outputs have made significant impact across many fields of science and industries.

For science programmes the Institute

- produced many of the mirrors of NASA’s James Webb Space Telescope (the Hubble replacement)

- produced the science equipment that NPL used to re-define the temperature scale: the Boltzmann constant facility

- produced the large prototype aspherised mirror segments of European Southern Observatory’s Extremely Large Telescope

- designed and built a large scale reactive atom plasma figuring system that can figure correct optics used in fusion energy research facilities

For industry the Institute

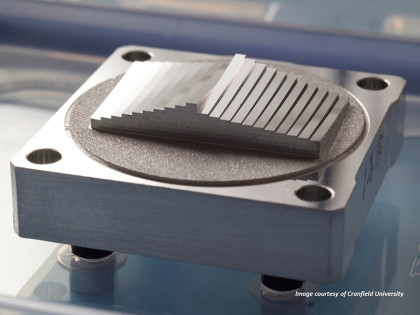

- designed, created and operates the world’s leading facility producing large ultra precision structured drum tools for reel to reel production of advanced films. Over 24 companies worldwide are using this facility to create their film based products

- designed and built a highly compact ultra precision micro-milling machine capable of producing advanced infra red (IR) optics and watch components. This is being commercially exploited by a Cranfield spin-out company

- designed and built a highly compact ultra precision micro-milling machine capable of producing advanced infra red (IR) optics and watch components. This is being commercially exploited by a Cranfield spin-out company

- designed and built an ultra precision grinding machine for production of free form optics for advanced lithography optics fabrication. This is being commercially exploited by a Cranfield spin-out company

All of the Institute’s laboratories are managed under strict health and safety guidelines and access is controlled to ensure it offers customers security and Non-Disclosure Agreement (NDA) compliance is maintained.

Access to leading precision engineering equipment is available on a commercial contract basis or through research collaborations. Laboratories include:

Hexagon Loxham Laboratory

Capacity to grind, polish, plasma process and measure ultra precise free-form optics of up to 1.5 metres with unrivalled production rates.

Find out morePrecision Metrology Laboratory

Houses ultra precision co-ordinate metrology systems of up to 3 metre capacity.

Find out moreUltra Precision Machining Laboratory

Housing a range of Cranfield own developed ultra precision diamond turning machines and those from leading suppliers.

Find out morePrecision Machine Assembly Laboratory

A highly temperature controlled and clean machine tool development laboratory used for the construction, build and commissioning of precision and ultra precision machine and production systems stemming from our machine technology and renewable energy research programmes.

Find out moreMicroengineering Laboratory

Thermally controlled laboratory housing a five axes precision micromilling machine, a microinjection moulding machine and an optical and contacting probe miniature co-ordinate measuring machine.

Since the establishment of the Cranfield Unit for Precision Engineering (CUPE) we have a firm commitment to world-class precision engineering expertise.

Find out more