Precision Engineering Industrial Short Course, Cranfield University.

2017 date to be confirmed

A highly practical, results orientated five day intensive short course covering the basic principles and state-of-the-art concepts to increase the precision, accuracy and reliability of machine tools and products.

This course is based on the highly successful short course series developed by Professors Pat McKeown, John Corbett and Paul Shore at Cranfield University. It has previously been provided in Europe, the USA and numerous Asian countries during the last 20 years. With constant updating of content and with newly engaged internationally renowned instructors, this course offers a unique blend of the most current technical knowledge.

Suitable for engineers in the machine tool, automotive, aerospace, optics and semiconductor industries. It is highly appropriate to individuals involved in purchasing high value precision engineering facilities where accuracy capability is critical to profitability and success.

Outline course content

High precision machine tool metrology

- Introduction to Precision Engineering

- Background, application sectors, industrial trends

- Underlying philosophies of precision engineering

- Assessment of machine performance

- Dynamic performance

- Static performance (machine calibration)

- Machine Metrology and Calibration

- Metrology general concepts of traceability, calibration and correction

- Calibration methods – artefact effect, global methods, parametric methods

- Geometric parameters

- On-machine workpiece metrology

- Measurement strategy (in-cycle, in-process, process capability)

- Areal techniques

- Geometric, texture and surface integrity measurement

- Geometrical tolerancing, standards and definitions

- CMM fundamentals, configurations operation and use

- Surface topography instruments

- Profile and areal surface texture measurement

- Optical metrology for ultra-precision components

- Optical microscopes (white light, confocal and scanning instruments)

- Wide aperture interferometry

- Metrology case studies

High precision process technology

- Process chain engineering for ultra-precision surface creation

- Preamble of contact mechanics

- Birth of ductile-regime machining from nanoindentation

- Ultra-precision turning

- Single-point diamond machining

- Ductile-brittle transition and tool wear problem

- High-precision hard turning of ferrous components

- Ultra-precision abrasive machining

- Grinding and polishing

- Integrated simulations in the context of precision manufacturing

- Introduction to multiscale simulations

- Post-processing

- Working with high performance computing centres

- Hands on sessions and case studies (Access to Desktop preferred)

- Functional surface coatings

- Deposition methods, challenges to manufacture & surface preparation

- Multilayer and nanocomposite coatings

- Analytical methods

- Optical & astronomical coatings

- Self-cleaning and self-healing coatings

- Process design case studies

Dr Saurav Goel

An experienced lecturer, possessing considerable expertise on multi-scale modelling and experiments on manufacturing in general but machining difficult-to-cut materials in particular SPDT and hard turning. Current research interests include deterministic manufacturing solutions for large-scale optics manufacturing.

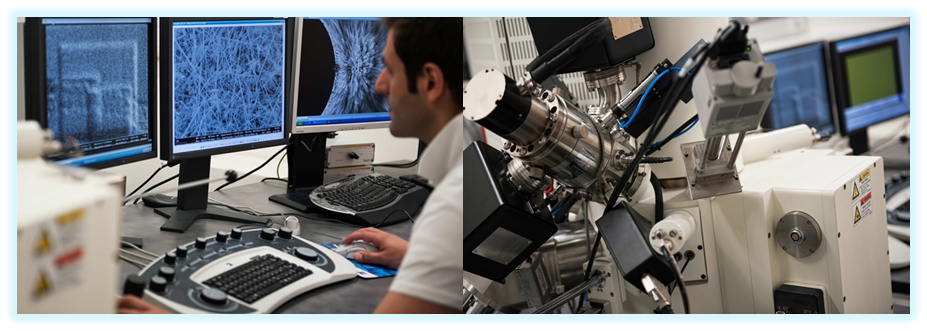

Dr Claudiu Giusca

Claudiu Giusca’s expertise is in the metrology associated with the use of optical surface topography measuring instruments, surface texture and micro-coordinate measurements and analysis, design and build of primary instrumentation and in-line optical 2D/3D hybrid systems.

Dr Jeff Rao

Jeff Rao has extensive and diverse experience and expertise in the deposition of PVD and other functional coatings. Jeff has worked in diverse areas including automotive and aerospace. He has been the key project manager in significant programmes, which have produced IP related to the deposition of self-healing polymeric coatings designed to minimize wear and reduce friction.

The course fee will include tuition, course notes and materials, refreshments and lunches and the course dinner, but does not include accommodation. Short Course accommodation packages are available on campus at Mitchell Hall on a bed, breakfast and dinner basis, subject to availability. Please state interest when registering for the course.

Lab demonstrations will also take place by Micro Epsilon, Aerotech and Goodfellow.

Further Information and Registration Further Information and Registration

Short Courses are subject to Cranfield University’s terms and conditions. We reserve the right to amend published information.

Ultra Precision Machining Technology Short Course, Cranfield University

2017 date to be confirmed

A two day intensive short course covering the basic principles and state-of-the-art machining technology.

This course has developed from the highly successful short course series developed by Professors Pat McKeown, John Corbett, David Allen and Paul Shore at Cranfield University, that has been provided in Europe, USA and the Far East during the past 20 years. With constant updating of content this course offers a unique blend of the most current technical knowledge.

Suitable for engineers in the machine tool, automotive, aerospace, optics and semiconductor industries. It is highly appropriate to individuals involved in purchasing high value precision engineering facilities where form accuracy, surface roughness and surface features capability are critical to profitability and success.

Course topics:

- Introduction and overview of precision engineering

- Abrasive machining processes

- Fixed abrasive machining

- Surface characterisation (contact and non-contact)

- Thermal effects in machine tools

- Metal cutting principles

- Single point diamond turning

- Non conventional machining (plasma based processes)

- Precision loose abrasive processes (CNC polishing)

- Non conventional machining

- Dynamic performance of machine tools

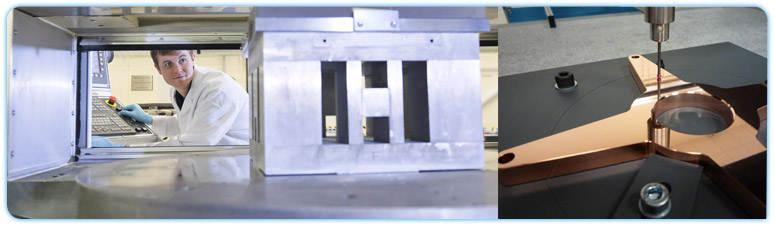

- Laboratory visits at Cranfield University

Course speakers

Dr Saurav Goel is an experienced lecturer, possessing considerable expertise on multi-scale modelling and experiments on manufacturing in general but machining difficult-to-cut materials in particular SPDT and hard turning. Current research interests include deterministic manufacturing solutions for large-scale optics manufacturing.

Dr Claudiu Giusca’s expertise is in the metrology associated with the use of optical surface topography measuring instruments, surface texture and micro-coordinate measurements and analysis, design and build of primary instrumentation and in-line optical 2D/3D hybrid systems.

Dr Jeff Rao has extensive and diverse experience and expertise in the deposition of PVD and other functional coatings. Jeff has worked in diverse areas including automotive and aerospace. He has been the key project manager in significant programmes, which have produced IP related to the deposition of self-healing polymeric coatings designed to minimize wear and reduce friction.

Dr Konstantinos Salonitis is a Senior Lecturer in Manufacturing Systems, and the Manufacturing Systems and Management Programme Director at Cranfield University. His expertise is in the modelling of manufacturing processes. His research interests include laser manufacturing processes, additive manufacturing and casting. His research in grinding processes has resulted in numerous publications that have been widely cited.

Short Courses are subject to Cranfield University’s terms and conditions. We reserve the right to amend published information.

Energy Beam Processing Short Course, University of Cambridge

2017 date to be confirmed

A short course aimed at providing delegates with an understanding of the ways in which energy beam technologies are used to deliver ultra precision materials processing capabilities in engineering applications.

Course Aims

The aims of this course is to provide participants with an understanding of the ways in which energy beam technologies are used to deliver ultra precision materials processing capabilities in engineering applications. The course focuses on two key energy beam technology systems widely applied in a number of ultra precision manufacturing applications. Strong emphasis is placed on presenting the underlying science of laser and ion beam technologies and the systems that deliver them. Methods are both theoretically and practically explored in a number of application case studies. The course will also provide delegates with both an understanding of issues and the practical means of dealing with these advanced ultra precision manufacturing solutions.

Course Content

Part 1 – Ion Beams

This part of the course covers a wide range of lithography and processing techniques. The emphasis is to provide delegates with an awareness of where ion beam lithography tools are applied in manufacturing operations. Subjects covered include:

- Optical lithography

- The current status of EUV lithography

- Beam sample interactions

- Basics of ion beam lithography

- Electron beam lithography 1

- Electron beam lithography 2

- Alternative lithography techniques 1

- Alternative lithography techniques 2

This section of the course covers a wide range of laser system technologies and micro materials processing techniques. The emphasis is to provide participants with awareness of how and where laser beam micro processing tools are supplied in ultra precision manufacturing operations. Subjects covered include:

- Generation of laser light

- Laser source technologies

- Laser beam characteristics

- Laser beam manipulation

- Laser matter interactions

- Materials processing

- Laser system technologies

- [Laser based micro processing applications

- Understand core scientific underpinning and engineering delivery and applications of energy beam technologies

- Have a thorough appreciation of how energy beam technologies are used in the fabrication of ultra precision devices

- Be able to assess and utilise appropriate technology choices for the production of ultra precision components

- Understand the operation of and the practical means of applying energy beam technologies in an ultra precision manufacturing context

To find out more about this short course, please contact Sophie Fuller at the University of Cambridge.

Renewable Energy Policy, Modeling and Analysis of Potential

2017 date to be confirmed

Cranfield University offers this two-day short course providing an insight in the European energy policy and market. It will additionally give an introduction to renewable energy (RE) potential modelling within a Geographical Information System (GIS) environment.

This course offers an insight into the highly topical area of European energy policy. It will be of value to anyone wishing to gain a better understanding of the potential of various renewable energy technologies, their opportunities, and benefits at both regional and national scales.

Delivered through a combination of lectures and practical sessions, the course will allow delegates to broaden their knowledge of renewable energy policy and the European electricity market. You will learn how to carry out modelling at a local and national scale within a GIS environment.

The course will be of particular interest to scientists, engineers, managers, technologists and postgraduate researchers from the energy sector. It will also be valuable to manufacturing and engineering companies, policy makers, investors, research academics, technical professionals, technical staff and non-specialists who wish to gain a better understanding of the potential of the various renewable energy technologies, its opportunities and its benefits at a regional or national scale.

Speakers include

- Dr. rer. nat. Martin Pudlik, a scientific researcher in the Competence Centre Energy Policy and Energy Markets at the Fraunhofer Institute for Systems and Innovation Research (ISI)

- Dr Chris Sansom of Cranfield University, who is an internationally authority on Concentrating Solar Power.

Concentrating Solar Power

22-24 March 2017

Cranfield University has organised this specialist training course aimed to provide both theoretical and practical expertise in this rapidly growing technology and its applications.

Scientists and engineers who are currently engaged in energy and power generation need to be aware of recent global expansion in the building of CSP plants. This offers opportunities for the entire CSP supply chain, including component manufacturing. To meet this need for increased knowledge and understanding of CSP, Cranfield University has organised this specialist short course aimed to provide both theoretical and practical expertise in this rapidly growing technology and its applications.

The course will be delivered through a combination of lectures, practical sessions and a group exercise and will allow delegates to broaden their knowledge of solar collector designs and solar coating technology. The course will provide an overview of all aspects of concentrating solar power technology. It will also encompass CSP applications, giving delegates an awareness of its use for electrical power generation, heating and cooling, water desalination, the provision of industrial process heat, as well as off-grid medium and small scale cooking and water purification for remote regions of the world.

The course will be of particular interest to scientists, engineers, managers, technologists, and postgraduate engineers from the energy sector. It will also be valuable to manufacturing and engineering companies, policy makers, investors, research academics, technical professionals, technical staff and non-specialists who wish to gain a better understanding of CSP technology, its opportunities and its applications.

Speakers include

- Dr Chris Sansom of Cranfield University, who is an internationally authority on Concentrating Solar Power.

- Dr Peter Turner is the former Head of CSP Technologies at E-On and has over 30 years experience in the power industry.

- Dr Debabrata Bhattacharyya is leading research in infrared optics and thin film sensing coatings technology at Cranfield University.

- Dr Paul Kirby is a Senior Research Fellow in Concentrating Solar Thermal Materials and Manufacturing Technology at Cranfield University with previous research in MEMS.

- Dr Kumar Patchigolla is a Lecturer in Carbon Capture and Storage at Cranfield University.

- Dr Xavier Tonnellier is a Research Fellow in Precision Engineering at Cranfield University whose interests focus on large scale ultra precision surface technologies and process development.

- Dr Heather Almond is a Research Fellow in the Precision Engineering Institute at Cranfield University working on CSP technologies.

- Dr Peter King is a Research Fellow in Concentrating Solar Thermal Manufacturing at Cranfield University. Current research interests include assessment of solar collector shape with ground and UAV based photogrammetry.