Advancement of Plasma Figuring Technology to Reduce MSF Errors on Metre-Scale Optical Surfaces – Mr Nan Yu

This PhD project is focused on design, fabrication, and characterization of novel nozzles for Inductively Couple Plasma (ICP) torches that are used for the optical fabrication of metre scale surfaces. This research aims to increase the processing capability of the Plasma Ffguring method developed at Cranfield University. This aim will be achieved by creating highly collimated energy beams characterized by a material removal footprint between 1mm and 5mm FWHM (Full Width at Half Maximum). This research addresses the worldwide demand in ultra-precision surfaces. Three main aspects of this research work were achieved in the second year.

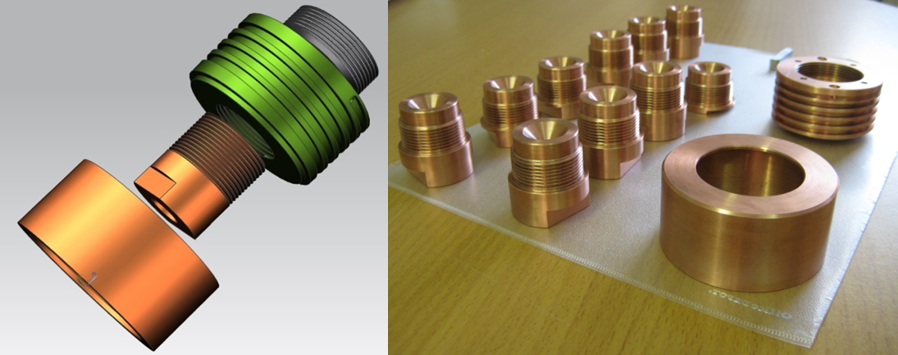

First, a CFD model based on the High Temperature Gas (HTG) was created for the current De-Laval nozzle used on the ICP torch. This achievement was obtained through two phases. A preliminary model was created and tested against the plasma torch model sourced in the literature. The results showed an acceptable degree of agreement. Thereafter the model was significantly amended to enable simulations in real processing conditions identical to those set in the laboratory during the Plasma Figuring process. Thus a comparison between the experimental material removal footprint and its counterpart predicted axial velocity profiles showed to be satisfactory. This numerical approach enabled investigation of aerodynamic behaviour of plasma jet. Moreover the model was found to allow rapid exploration of further nozzle designs. A set of new nozzles designed and manufactured are shown in Figure 1.

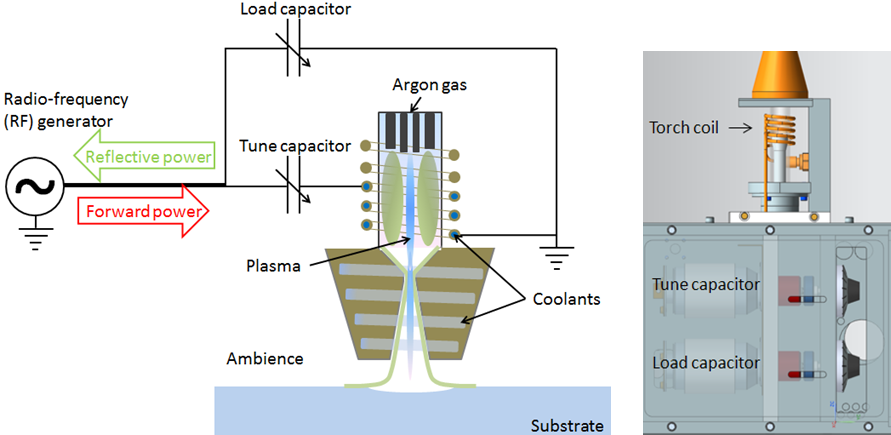

Second, the investigation of the RF network was carried out on the Plasma Delivery System (PDS) of Helios 1200 (Figure 2). The influences of three system parameters of the PDS were investigated, and an optimization was suggested. The selected electrical parameters of the PDS were load capacitance, tune capacitance, and the state of the induction coil. The results of this investigation enabled the determination of the most influencing parameters and a method for tuning the PDS. This investigation will be further utilized for the creation of a unique algorithm that will enable a couple of stepper motors to adjust automatically the impedance of the PDS. This work will consequently improve the performance and reliability of the Plasma Figuring process.

Third, an investigation of the energy dissipation rate that characterised best the ICP torch was undertaken. Fine temperature measurements and calculations were performed to determine energy dissipation rate values. Experiments were carried out in a very challenging environment where intense electromagnetic fields dominate and perturb signals provided by temperature sensors (Figure 3). Energy dissipation rate of the ICP torch was obtained from the temperature changes of its coolants. In addition, this work enabled the derivation of energy both provided for gas heating and lost by radiations. This investigation enabled a good understanding of the plasma figuring in term of energy dissipation rate. Also, the plasma average temperature derived from this energy dissipation investigation was found to be in a good agreement with that calculated through CFD model.

In the coming year, a set of footprint experiments will be carried out using the new set of De-Laval nozzles which were fabricated during the first year of this PhD. Experiments will be carried out to prove the deterministic aspects of the new nozzle. Finally, Plasma Figuring will be carried out to remove the MSF on optical surfaces and prove the fast figuring capability on the metre scale optics.

This research is being undertaken at Cranfield University under the supervision of Dr Renaud Jourdain and Dr Mustapha Gourma, Cranfield University and Prof Paul Shore, National Physical Laboratory.

Outputs

Journal Publications

Yu, N., Jourdain, R., Gourma, M. and Shore, P. (2016). Analysis of De-Leval nozzle designs employed for plasma figuring surfaces, International Journal of Advanced Manufacturing Technology, DOI: 10.1007/s00170-016-8502-y

Conference Publications

Yu, N., Jourdain, R., Gourma, M. and Shore, P. (2016). CFD analysis of an enhanced nozzle designed for plasma figuring of large optical surfaces, Poster abstract: Proceedings of the 16th International Conference of the European Society for Precision Engineering and Nanotechnology, 30 May-3 June 2016, University of Nottingham, Nottingham, UK, 459-460.

Yu, N., Jourdain, R., Gourma, M. and Shore, P. (2015). Investigation of power dissipation in a collimated energy beam, The 6th International Conference of Asian Society for Precision Engineering and Nanotechnology, (ASPEN 2015), 15-20 August 2015, Harbin, China.

Yu, N., Jourdain, R., Gourma, M. and Shore, P. (2014). Analysis of model design used for the creation of advanced energy beam, 29th Annual Meeting for the American Society for Precision Engineering, 9-14 November 2014, Boston, MA, USA.

Conference Presentations

Yu, N., Jourdain, R., Gourma, M., and Shore, P. (2016). Advancement of plasma figuring technology through optimisation of energy beam, Poster presentation at euspen‘s 16th International Conference and Exhibition, 30 May-3 June 2016, Nottingham, UK, P6.31.

Yu, N., Jourdain, R., Gourma, M. and Shore, P. (2016). Energy balance investigation of an inductively coupled plasma torch for plasma figuring, euspen‘s Special Interest Group Meeting: Thermal Issues, 17-18 March 2016, Prague, Czech Republic.

Yu, N., Jourdain, R., Gourma, M. and Shore, P. (2015). Investigation of power dissipation in a collimated energy beam, The 6th International Conference of Asian Society for Precision Engineering and Nanotechnology, (ASPEN 2015), 15-20 August 2015, Harbin, China.

Yu, N., Jourdain, R., Gourma, M. and Shore, P. (2014). Analysis of nozzle design used for the creation of advanced energy beam, 29th Annual Meeting for the American Society for Precision Engineering, 9-14 November 2014, Boston, MA, USA.

Yu, N., Jourdain, R., Gourma, M. and Shore, P. (2014). Analysis of nozzle design used for reducing the MSF errors in rapid plasma figuring, Poster presentation at the 3rd Annual EPSRC Manufacturing the Future Conference, 23-24 September 2014, Glasgow Science Centre, Glasgow, UK.

Posters

Yu, N. (2016). CFD analysis of an enhanced nozzle designed for plasma figuring of large optical surfaces, Poster presentation to the EPSRC Centre for Innovative Manufacturing in Ultra Precision Steering Meeting Committee, 24 February 2016, Cranfield University, UK.

Yu, N., Jourdain, R. and Shore, P. (2014). Reduction of Mid Spatial Frequency Errors on Metre Scale Optical Surfaces Using Rapid Plasma Figuring, EPSRC Centre in Ultra Precision Mid-Term Review, 20 May 2014, Cranfield University, UK.

Digital Media

Yu, N. (2015). Advancement of plasma figuring technology to reduce MSF errors on metre-scale optical surfaces, PhD project video produced for an informal Centre competition in 2015.