The Use of Ultrafast Laser Processing for the Removal of Ion Beam Implanted Gallium – Mr Matthew Bannister

This project aims to deliver an ultra-precise method of driving the removal of gallium ions implanted within substrates after focused ion beam micro-processing by using ultra-fast laser pulses below the optical damage threshold of the material.

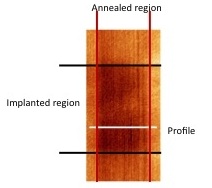

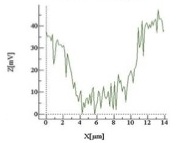

The effects of laser fluence on the removal of ion beam implanted gallium have been studied on silicon and glassy carbon. Substrates were implanted with gallium ions at a dose of 4.17 x 1021 ions/cm2 and subsequently processed using a 1030 nm wavelength, 280 fs pulse duration ytterbium fibre laser over a wide range of pulse energies. Changes in gallium ion concentration were measured using energy dispersive x-ray spectroscopy (EDX). EDX analysis showed that, for pulses with fluences below the damage threshold of the material, there was no change in overall gallium concentration, meaning that no removal from the surface occurred. However for pulses just above the damage threshold, the removal of a thin layer of substrate material resulted in a reduction in gallium ion concentration, as can be seen below. Further investigations into femtosecond laser polishing as a technique for removing ion beam implanted gallium are ongoing.

This PhD research project is being undertaken at the Institute for Manufacturing, University of Cambridge under the supervision of Prof Bill O’Neill and is sponsored by Carl Zeiss.