Emerson & Renwick is an independent company, founded in 1918 in Lancashire, England.

The original company has grown and developed in line with market changes, and today is a leading manufacturer of production machinery, in the areas of:

- Wallcovering Machinery

- Automotive/Heat Exchanger Machinery

- Coating and Laminating Machinery

Over the years, the company has grown with its acquisition of the Dixon Technologies and Fin Machine Company brands. These associations have supported Emerson and Renwick’s aim of a product range and company capability closely linked to the needs of the markets it serves.

With extensive, screen printing, gravure and hot embossing technology, Emerson and Renwick have played a vital role in the design and development of wallpaper manufacturing machinery enjoying a close relationship with leading manufacturers in the UK and across the world.

In addition to our coating technology, Emerson and Renwick are an experienced provider of Fin Mill, Corebuilder and Tube Mill Machines within the automotive heat exchanger industry. The acquisition of The Fin Machine Company (IP) has now broadened the range of machinery we can offer.

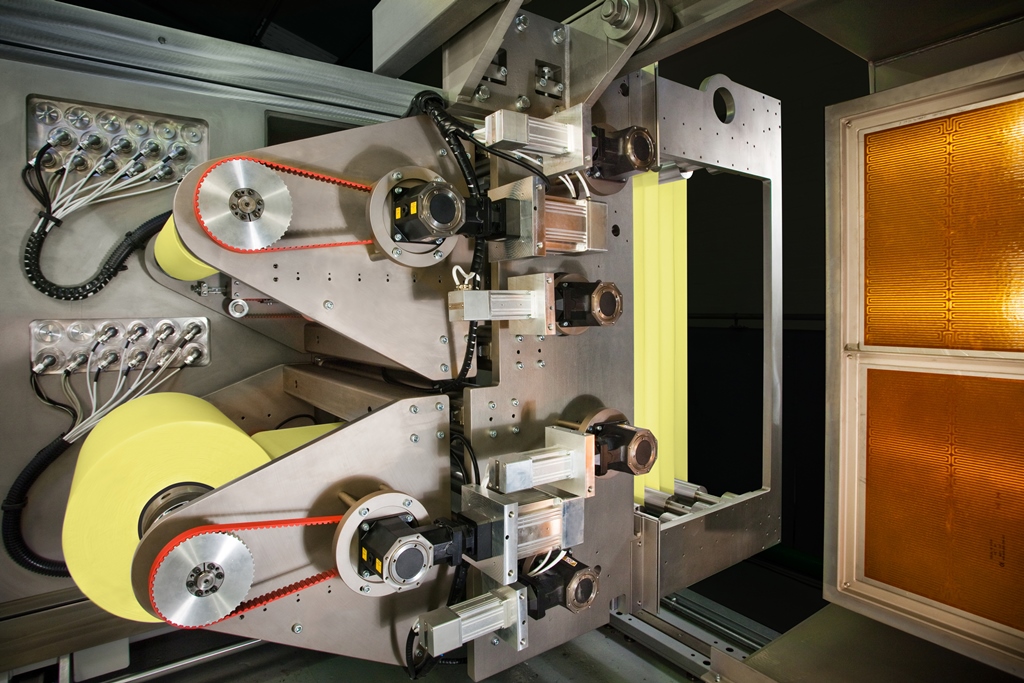

Emerson and Renwick manufacture atmospheric coaters for lamination, gravure, flexo, offset, hot melt etc under our Dixon Technologies brand and have the ability to put together both atmospheric and vacuum coating lines which we can tailor to suit the products individual needs. We have a record of continuously introducing roll to roll coating technology that has revolutionised a wide range of industrial machinery, through the supply of pilot coating, ultra high precision coating, custom and modular production lines.

We offer both end user and OEM platforms for specialist roll to roll applications and focuss on helping develop niche applications through a modular design and development strategy.

We have recently supplied vacuum coating machinery handling web based substrates up to 2.1m wide, including PECVD, sputtering and electron beam deposition. In Q2 2016 we will add to our demonstration centre an in-house modular vacuum platform available for prototyping.

We have both atmospheric and vacuum coating expertise on site to assist in process scale up when needed. We design, project and manufacturer nearly all equipment in our facility plant and so have a very strong vertical integration to working a project from inception to completion and are partnering with established source suppliers to bring to the market some novel coating, forming and deposition techniques for the wallpaper, automotive display, solar and securities industries with some pilot /production machinery.

We have recently designed a skid mounted pilot roll to roll sputter/e-beam/evaporation/PECVD compatible machine design for prototyping and initial production into the vacuum deposition market….specifically designed for next generation printed electronics and flexible semiconductor, and have recently invested in also offering ICP etching and ICP CVD capability in R2R format for up to 300mm wide webs and (500mm target).