Project Researchers: Sammy Yassine, Quentin Bonnardel, Domenico Siniscalco, George Zaganas and Hangtian Zhou

This research was undertaken as a group project within the Centre at Cranfield by a group of Manufacturing Technology and Materials MSc students during academic year 2013/2014.

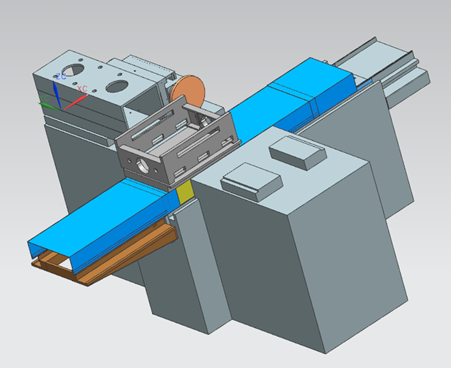

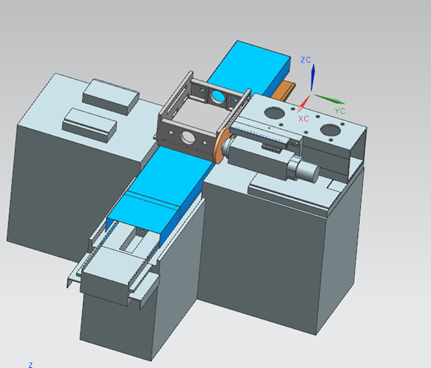

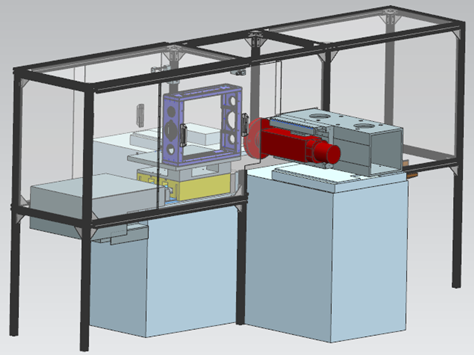

The project was linked to the meso platform, a highly compact 6 axes CNC ultra precision machining system. Its power density is high which demands its main structural components to be stress free after final machining. Those components will have to be diamond machined with tolerances lower that what is achieved in the industry.

The aim of the project was to specify, design, build and test an ultra-precision diamond machining system in an almost impossible time scale (80 days, 60 working days). The objectives were:

- Specify, design, build and commission a diamond machining system in only 80 days

- Process an aluminium frame of 611 x 492 x 215 mm having 25 nanometre RMS roughness and flatness of less than 5 µm on four of its faces

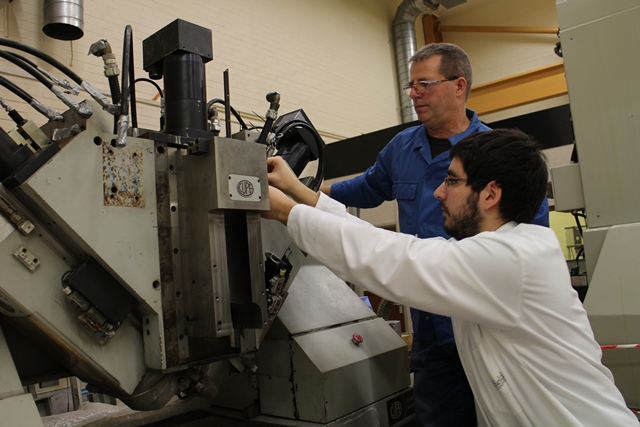

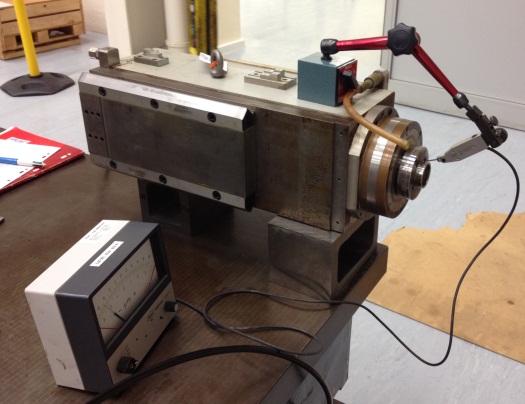

The first step of the project was to define the diamond machining specifications. A complete review of an obsolete grinding machine was then conducted in order to identify components that could be re-used: air bearings and spindles.

The design process was carried out with a scope ranging from mechanical parts design to electrical layout, using CAD modelling. Mechanical parts were sourced from local suppliers. The control system and motors were complimentary from Aerotech, and Renishaw offered the two encoders.

This MSc group project was sponsored by the EPSRC Centre in Ultra Precision with industrial support from Aerotech and Renishaw and was supervised by Professor Paul Shore and Mr Keith Carlisle.