Project Researchers: George Meakin, Jason Ten and Matthew Pryn

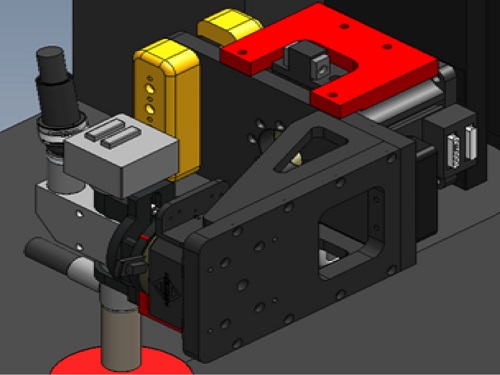

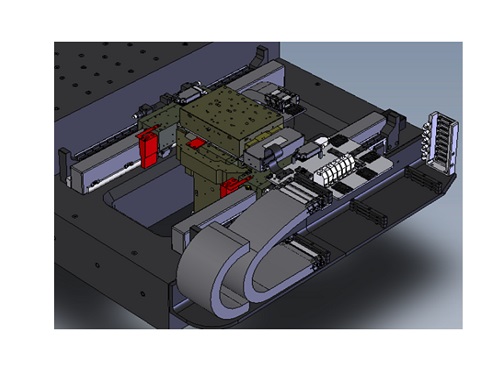

The goal of this three person group project was to design an ultra precision laser machining platform suitable for integration with a FIB system, as part of the Centre’s Nano FIB platform. The laser system should be able to add or remove material (resolution 200 nm) from a sample wafer (50mm in diameter), so that FIB machining can be used to finish the process with high accuracy (resolution of 30 nm). Because a laser can remove material far faster than an FIB, relatively large structures can be completed with near FIB accuracy using this method, in a fraction of the time for only using the FIB.

The laser platform should also be suitable for research into laser machining, and for microstructure and MEMS development. Laser positioning accuracy is a major focus for this machine. Commercially available laser machining platforms have a larger working volume and relatively poor accuracy, making them unsuitable for ultra precision application. Because of the diverse potential uses of this technology, the platform required a large degree of flexibility, with multiple lasers and optical setup options made available to user. The user must also have the ability to quickly and easily set-up and calibrate the desired configurations.

The outcome of the project saw the students deliver full design solutions for the laser machining station that placed it ahead of any commercial laser machining station in terms of positioning accuracy, control, and features. The use of in-process metrology was specified, and both an optical coherence tomographic system and a multi-wavelength holographic system were chosen as the main in-process inspection technologies. Fully automated mirror mounts and laser beam positioning will enable the device to be quickly and precisely reconfigured for each process configurations and process operation. These options include single spot laser machining; array based laser machining using re-programmable holographic projectors and high speed laser scanning systems utilising electro optic modulators. Three laser source technologies operating at ns, ps and fs timescales were chosen for the processing station and full error mapping and reporting were performed in order to fully specify the system and its overall production capabilities. The technology and system components are now in the procurement/development phase, and the unit is set to be completed by October 2014.

This MRes group project was undertaken at the University of Cambridge during academic year 2013-2014.